- Meta has developed an open-source AI tool to design concrete mixes that are stronger, more sustainable, and ready to build with faster—speeding up construction while reducing environmental impact.

- The AI tool leverages Bayesian optimization, powered by Meta’s BoTorch and Ax frameworks, and was developed with Amrize and the University of Illinois Urbana-Champaign (U of I) to accelerate the discovery of high-performance, low carbon concrete.

- Meta successfully deployed a concrete mix that was optimized with the AI tool at a data center construction site. Being open-sourced and freely available, the AI-tool could help increase the adoption and optimization of sustainable concrete mixes in the construction industry at large.

Low carbon concrete solutions are essential for advancing our goal of net zero emissions in 2030. Concrete production is a major contributor to the embodied carbon emissions in data center construction and accounts for 8% of all global CO2 emissions, according to the World Economic Forum.

Conventionally, concrete is optimized for strength (28-day compressive strength) and cost. But modern constructions – including data centers – require concrete that is optimized for sustainability, curing speed, workability, and finishability as well.

Innovation in concrete formulations is difficult and slow. Compared to traditional concrete, current formulas for low carbon concrete face several challenges: slower curing speeds, issues with surface quality, and complications in supply chains when novel materials are involved.

But concrete suppliers can utilize AI to develop and scale innovative concrete mixes as drop-in replacements, accelerating the discovery and integration of sustainable materials for large-scale use.

By collaborating with Amrize — one of the world’s largest cement manufacturers and major concrete suppliers — and the University of Illinois Urbana-Champaign (U of I), we’ve developed an AI model and pipeline to accelerate the discovery of new concrete mixtures that meet traditional requirements alongside newer sustainability needs.

Our work with Amrize and U of I has already resulted in the successful design and deployment of AI-designed green concrete at our new data center in Rosemount, MN.

Meta’s AI model for green concrete

Designing concrete formulas is a complex, multi-objective problem. The designer must choose between various types and proportions of cement, lower-carbon supplementary cementitious materials (SCMs), water-to-binder ratios, coarse and fine aggregate types, and admixtures. SCMs’ impact on concrete performance varies by source location and seasonality, requiring long-term tests for validation. Finally, time-consuming tests taking days and weeks are needed to fully validate the performance of new mixes. Thus, it is important for the design process to be as efficient as possible.

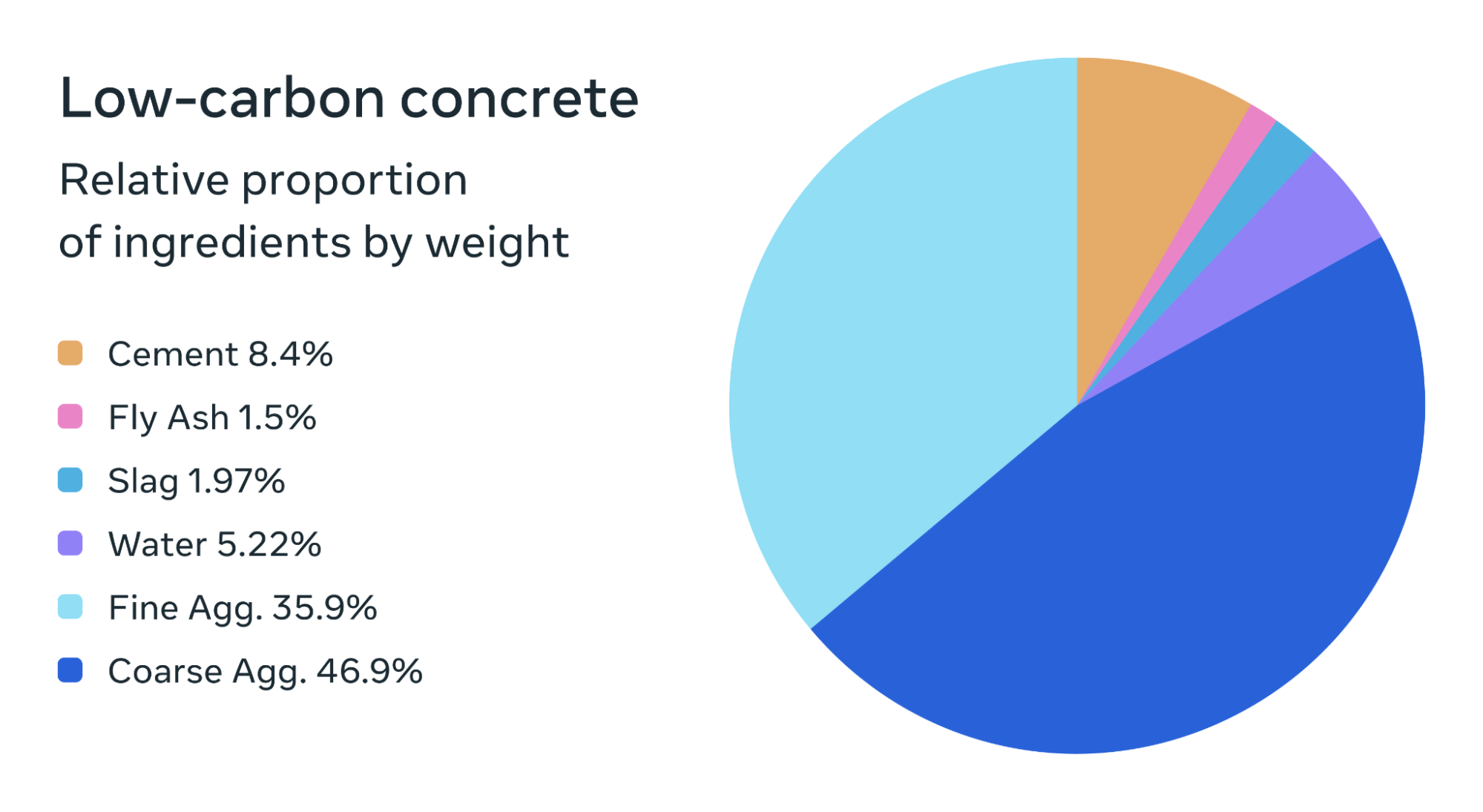

There are several key ingredients often used in a sustainable concrete mix:

- Cement is the “glue” that holds concrete together. It’s made from calcining limestone, clay, and other minerals in a high-temperature rotary kiln – the process which contributes significantly to CO2 emissions. The cement is then mixed with water, SCMs, aggregates, and admixtures at a ready mix plant to create concrete. When the cement paste hydrates and stiffens over time, it forms a hard, binding gel that gives concrete its strength.

- Slag is a byproduct of steel production. It’s a molten waste material that’s cooled and ground into a fine powder. In concrete, slag helps reduce concrete’s embodied carbon by replacing cement, and improves long-term strength, durability, and resistance to external chemicals.

- Fly ash is a type of industrial by-product from coal-fired power plants. It’s collected from the air pollution control systems and can be used as a substitute for some of the cement in concrete. Fly ash helps reduce the embodied carbon in concrete by replacing cement, and also improves its long-term strength, durability, and workability.

- Fine aggregate, like sand, is smaller than coarse aggregate and fills in the gaps between the larger rocks or gravel. Sand helps to create a smooth, even surface, and improves the overall texture of the concrete.

- Coarse aggregate refers to crushed stone or gravel that are added to concrete to provide bulk volume and load-bearing capacity, helping the concrete resist cracking and shrinkage.

Mixing these ingredients together in different proportions gives rise to concrete with varying strength and sustainability properties. The properties of each ingredient varies by origin and condition of manufacturing. Furthermore, some of the SCMs are declining in availability, necessitating the discovery and incorporation of novel materials for which little-to-no data is available. All of this adds to the challenges of concrete design. The goal of our approach is to optimize the trade-off between strength and sustainability.

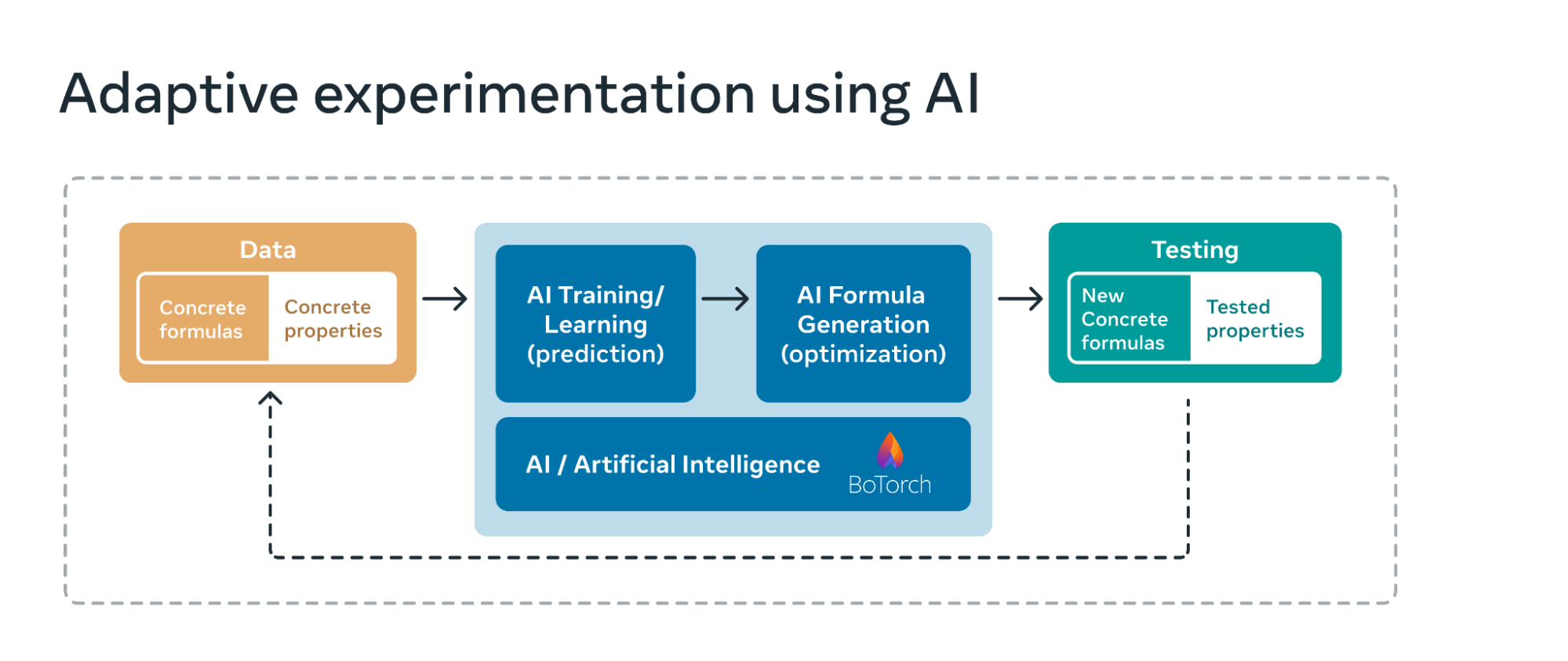

To accelerate the concrete mix design process, Meta developed an AI model for sustainable concrete using BoTorch and Ax, Meta’s open-source software for Bayesian optimization and adaptive experimentation, respectively. This model uses multi-objective Bayesian optimization algorithms to learn and optimize concrete compositions. The approach predicts compressive strength curves for different mixtures, optimizing short- and long-term strength properties and sustainability.

(For technical details of the model and optimization algorithm, see our technical report, “Sustainable Concrete via Bayesian Optimization” and our open source SustainableConcrete repository with the associated data and code.)

The basis of the approach is a model that predicts the compressive strength curves associated with different concrete mixtures.

The figure below shows an example of two strength curve predictions, one associated with a concrete mix including pure portland cement (purple)—the most commonly used type of cement—and a second one where a part of the cement was substituted by fly ash (blue), whose carbon impact is lower than that of cement. We then leveraged the strength predictions at various times to jointly optimize the short- and long-term strength properties, as well as the sustainability of the associated mixes, to generate new formulas that can be validated through testing.

By using AI, we can accelerate the discovery process and drive efficiency in the experiment process.

To train this AI model with real data, we collaborated with Professor Nishant Garg and his research group at U of I. In each iteration, the AI suggests new promising concrete mixes based on performance predictions, which are updated with the latest data. We validated these predictions with lab testing and used the results to refine the AI for subsequent iterations. Our AI pipeline consists of the workflow of generating baseline data, training an AI model, using it to develop and validate new hypotheses, and then improving the baseline data and AI training.

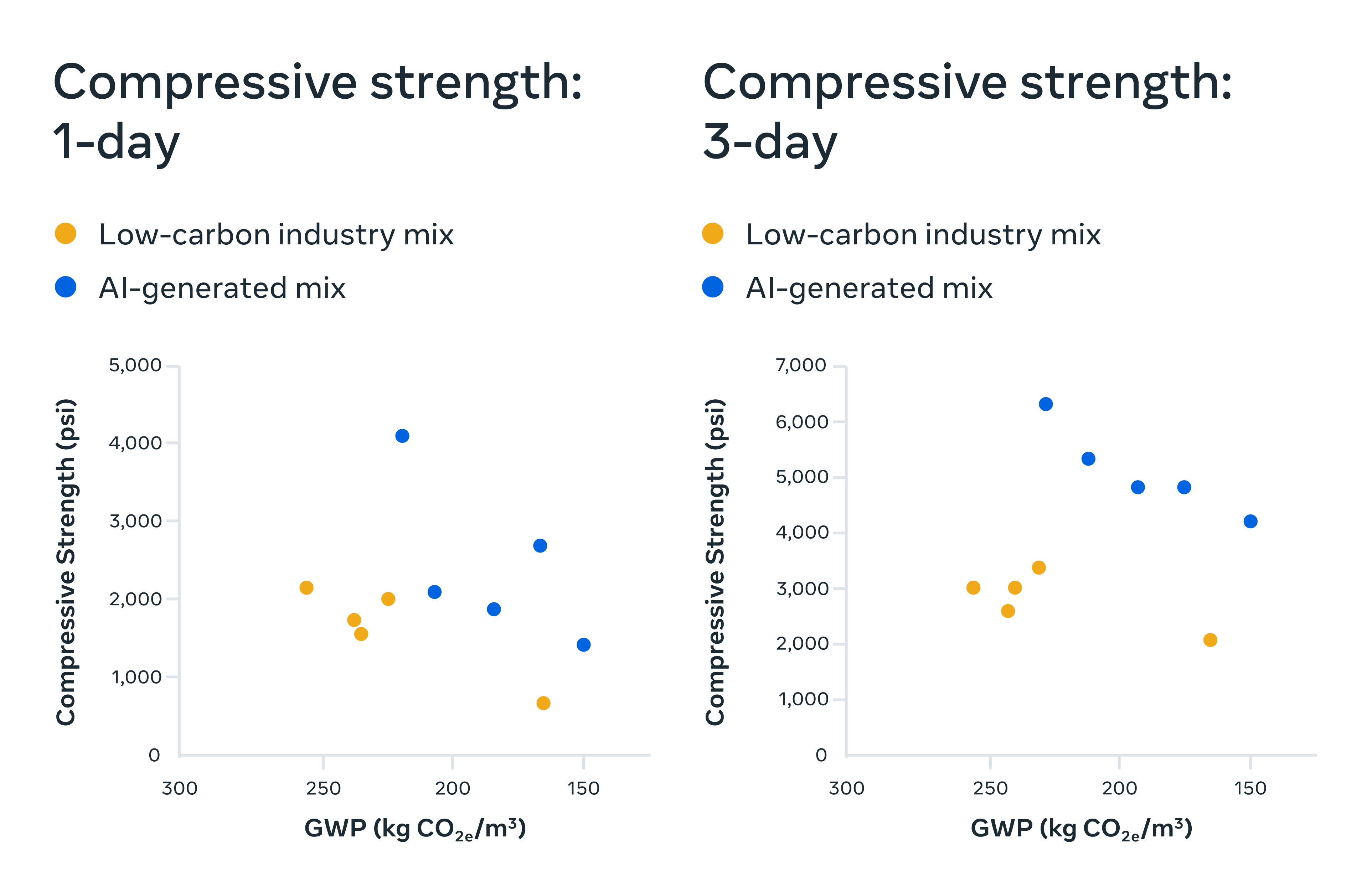

In implementing the first AI pipeline, we focused on several key metrics: compressive strength, curing speed, slump, and sustainability, which we quantify using a proxy for the carbon footprint of the concrete mix. The compressive strength of concrete is crucial for determining both its long-term structural integrity, typically specified as its 28-day compressive strength, and its short-term curing speed, specified as the time needed to achieve certain strength requirements such as strength one, three, and five days after the pour. When densely sampled x-day strength data is available, a strength curve can be generated.

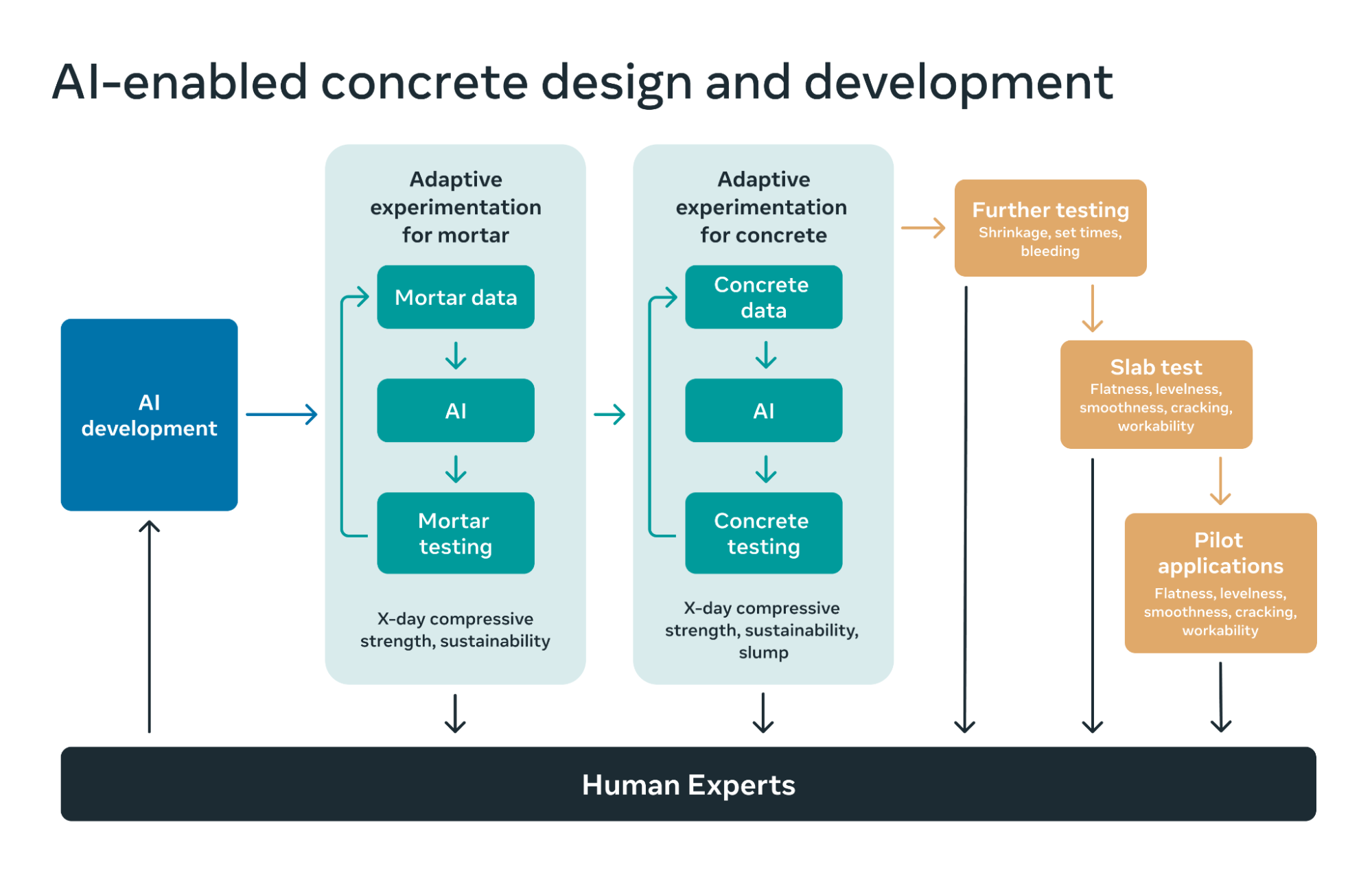

These attributes can be tested on concrete cylinders in the lab, allowing for rapid and systematic data generation necessary for training the AI. Larger-scale tests can be conducted after the new formulas, discovered through iterative testing, have been reviewed by concrete experts. By conducting research and development in stages, we can focus the AI on critical metrics and expedite progress.

The resulting AI pipeline is illustrated below:

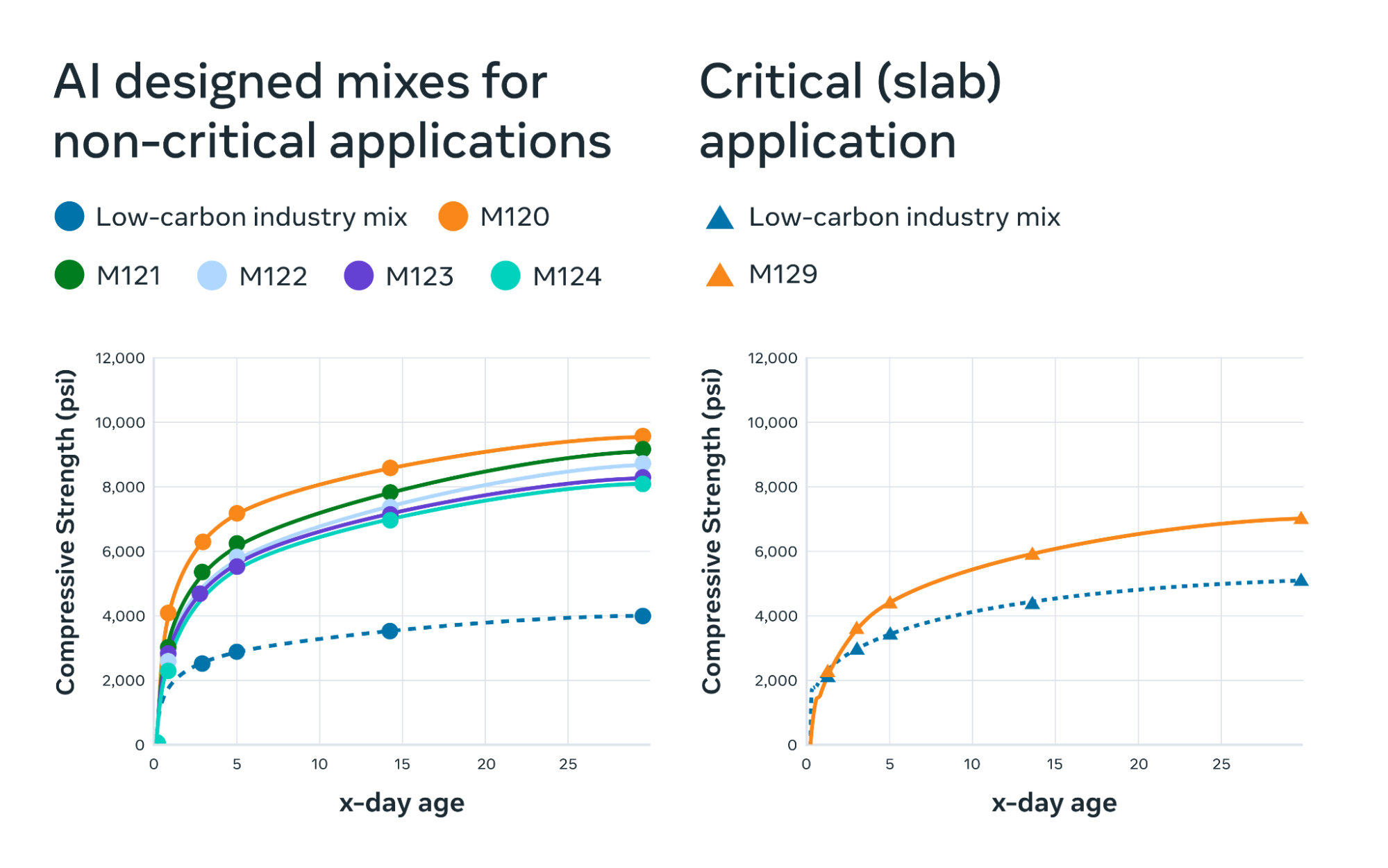

The figure below shows how AI is able to learn and further optimize x-day strength versus sustainability (quantified using a proxy for the carbon footprint of the concrete mix) over several iterations, exceeding the initial human-designed formulas.

Over time, this AI pipeline has generated high-quality data for AI training and development, containing over a hundred unique concrete mixes, comprehensive x-day compressive strength data, and global warming potential (GWP, measured in terms of kilograms of CO2 per cubic meter).

Developing an AI pipeline for industrial green concrete

In 2024, we started collaborating with Amrize to explore how Meta’s AI can be used at scale in the concrete industry.

Amrize shared basic concrete performance data, supporting Meta’s open source approach. They developed an AI pipeline at their batch plant near St. Paul, MN, extending the discovery and testing process.

Critical to data centers are the concrete slabs that serve as surfaces for deploying servers and associated power and cooling equipment. Data center slabs to be flat, level, smooth, and durable to enable reliable servicing of the equipment that reside on it. Therefore, their concrete formulations must meet additional high-quality finish requirements. Our AI algorithms incorporate specific water-to-binder ratios and volumetric material constraints, and discover high-performing formulas with faster curing and lower GWP values that meet the stricter requirements.

Distinguishing between formulas suitable for slabs, and those more suitable for other applications, we can compare their performance against industry standard formulas (see below). Within two iterations, and with minor human adjustments, the AI pipeline discovered formulas that exceeded standard low carbon industry formulas in terms of strength, speed, and sustainability.

Applying Amrize’s AI-designed concrete formulation at Meta’s Rosemount data center

Further testing is needed to apply AI-generated formulas in real-world applications. We therefore extended the first AI pipeline to incorporate additional steps and further tests, as shown in the figure below.

Amrize collaborated with Mortensen, a general contractor responsible for the construction of our datacenter, to test the new formula’s workability and finishability. Successful slab tests led to at-scale application in a site support section in one of the data center building slabs at Meta’s Rosemount, MN data center project.

Formal tests show that the team exceeded all the technical requirements while achieving good workability and finish performance required for the application.

Open source for more sustainable construction

At Meta, we believe AI can generate high-performance, low carbon concrete mixes for major construction projects such as data centers. Open source AI can benefit every level of the construction industry, from the construction companies and contractors, to suppliers, providers, architects, and, of course, building owners.

We will continue our collaboration with Amrize to further scale the use of AI in the concrete industry. The basic AI solution will remain open source to enable further commercial productization, application, and R&D.

Our aim is to scale the use of low carbon concrete in data centers and encourage the adoption of performance-based requirements at minimum risk. Meta will continue to engage with other hyperscalers to collaboratively test and prove low carbon concrete formulas to further decrease carbon emissions. Meta will also leverage organizations such as iMasons and the Open Compute Project to publish reference designs, AI-informed formulas, case studies, and best practices.

Learn more about Meta’s AI for sustainable concrete

- Download the sustainable concrete AI model on GitHub.

- Read our technical report, “Sustainable Concrete via Bayesian Optimization.”

- Learn more about BoTorch and Ax.

- Read more about how Meta uses low carbon concrete in our data centers.